Retail

In-store presentation is the final step to manage before the fruit reaches consumers.

Managing fruit display will not only improve consumers' shopping and eating experience, but is likely to increase your sales rate. This section will guide you in how to optimise your fruit on-shelves.

Display kiwifruit prominently

In the retail store, place kiwifruit in a prominent position with other mainstream fast-moving fruits. Once ripened, kiwifruit produce their own ethylene. Placing ripe kiwifruit on a retail shelf next to ethylene-producing fruit is not a concern.

Keep fruit in its tray or pack

To avoid fruit damage and maintain traceability, try to leave the fruit in its packaging for retail presentation. If it is supermarket policy to mount fruit for display, then layer fruit no more than 4–6 deep and check fruit quality frequently.

Rotate the softest fruit to the front

Rotating the softest fruit to the front of the display increases sales of ready-to-eat fruit and minimises shrinkage.

Display fruit that are close to the optimal eating firmness range

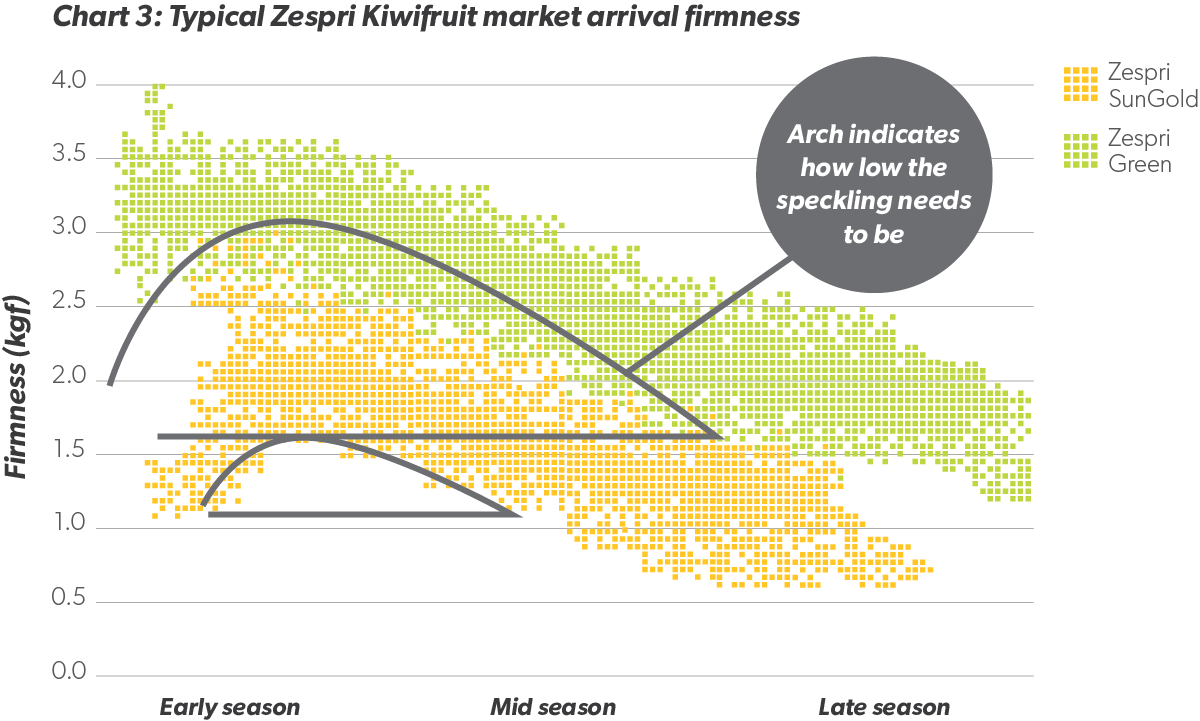

Try selling Zespri Kiwifruit at a firmness that is ready-to-eat or only marginally above to optimise the consumer eating experience and repeat sales. Support sales by serving in-store ready-to-eat samples.