Sample Selection

All fruit can be variable in its quality and kiwifruit is no exception. There can be variation between grower lines, pallets, packs and pieces of fruit. It is critical to take a representative sample of your fruit when attempting to assess its condition.

Depending on the activity (e.g. receiving fruit, holding fruit in storage or ripening fruit) you will need to adjust your assessment protocol, always ensure you -

-

Assess fruit as soon as possible after delivery to ensure you identify any potential issues

-

Select sample pallets from different locations in your coolstore or container (e.g. front, middle, back).

-

Try to assess packs near the centre of the pallet (not the top two rows).

-

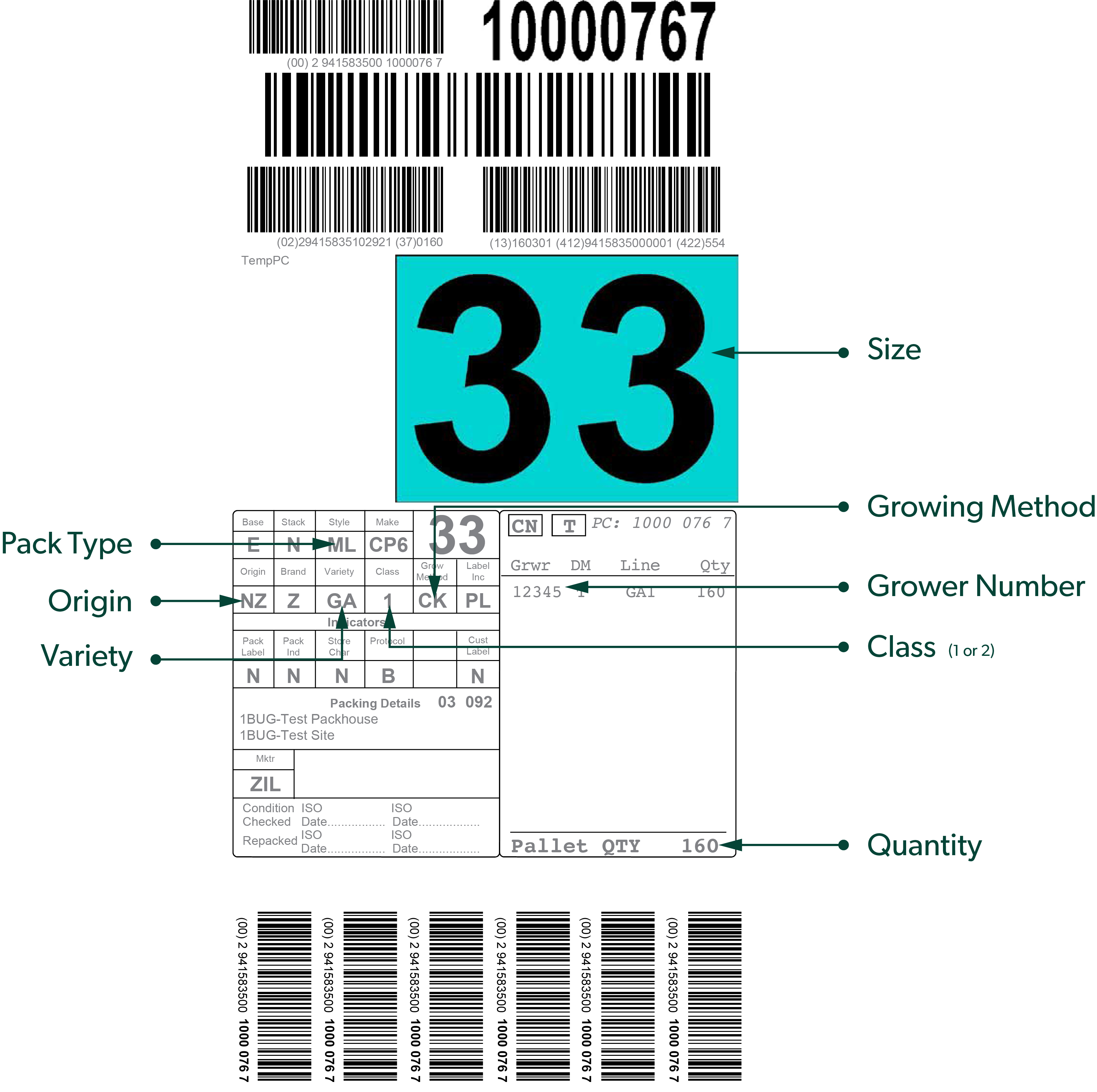

Identify the different grower lines on the pallet (using the pallet card) and target the majority grower. This is especially important when ripening fruit as all grower lines ripen at different rates.

Insert container plan graphic from ‘recommended sample selection’ page [To be provided by Zespri}

Pack selection

Identify the majority growers: when choosing which packs to sample, be mindful that some pallets contain a number of growers. Where possible, it makes sense to identify the majority grower on the pallet (this grower’s packs should account for the bulk of your sample.) To identify the majority grower line, simply look at the pallet card details attached to the pallet (link to pallet card).

Select packs from different locations: take samples from throughout the pallet. It is best practice to include some packs from the centre of the pallet in your sample as the centre temperature can sometimes differ to pallets on the outside of the pallet. Avoid taking your entire sample from packs where you expect the firmest or softest fruit to be. Insteadake a representative sample from different parts of the pallet.

Insert pack graphic from ‘recommended sample selection’ page [To be provided by Zespri}